PrecisionGrinding Services

At China Precision Parts, we bring value to our partners by providing a wide spectrum of complete manufacturing services that allow firms to get more done under one roof. It’s simple: fewer set-ups = quicker deliveries and less overhead. We have outfitted ourselves to take mid-volume productions all the way from CNC machining to grinding to even shipping and packing.

We offer precision grinding services for every type of material, meaning we can service any industry. Grinding services help us create smooth surfaces or do precise shaping. Best yet, we can move a product from machining to grinding with nimble turn-around.

Could you benefit from a shop that can handle your full production? Visit our contact page and begin discussing your project with one of our engineers today.

Surface Grinding Processes

Kremin employs over a handful of surface and outside-diameter grinders in our shop to ensure we have the right machine for any material or application.

Honing/Shaping Processes

Our grinding center also includes a jig grinder and honing machine for creating shapes and holes with the highest caliber of precision. We understand that accuracy is essential in every step of the process.

Our Equipment

Grinding Equipment

| Qty. | Type | Capacity |

|---|---|---|

| 1 | Karstens Universal OD Grinder | 10″ Swing x 20″ Centers |

| 1 | Myford OD Grinder | 4″ Swing x 10″ Centers |

| 2 | Reid Surface Grinders | 6″ x 18″ |

| 1 | Okamoto Surface Grinder | 10″ x 24″ |

| 1 | SuperTech Surface Grinder (1) NEW in 2014 | 10″ x 24″ |

| 1 | Brown & Sharpe Surface Grinder w/ digital readout | 6″ x 18″ |

| 1 | Moore G18 Jig Grinder | |

| 1 | Sunnen mb 1660 HONE | .125″ Dia. – 6″ Dia. |

Related Articles

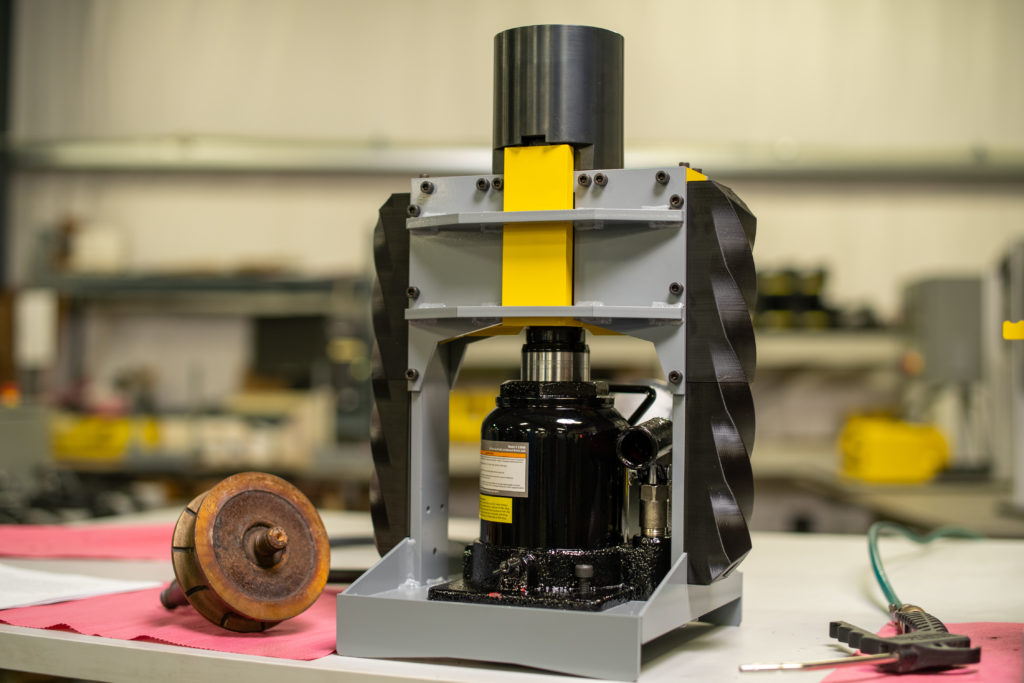

Does your diamond profiling tool keep getting caught in the cone? Spending too much resources on EDM? It can be tricky to get tooling unstuck, and it’s costly to just replace them. With our solution, the AdVice Press Stand, you can safely and easily remove tools from a cone, even if it’s worn down and … Continue reading The AdVice Press Stand for Stone Shops

Dimensional stone manufacturing is very hard on the equipment and can damage tooling over time. Damaged tooling in turn can damage a machine, adding up in costs! You can prevent this. Take our tips on inspecting and maintaining your stone toolholders and pull-studs now!