Quality ManagementSystem

Our Quality Management Software is integrated with our Enterprise Resource Planning (ERP) system to give us reliable information and history of all our parts and jobs. We maintain device master records as well as device history records for each job in our system. We also maintain an extensive library of quality forms. If your company creates its own documents, we can use those too.

At China Precision Parts Corp., our quality system meets or exceeds industry standards for medical, energy, defense, aerospace, and industrial sectors. We work with a robust group of sub-vendors who share our belief that quality is the top priority. A network of National Aerospace and Defense Contractors Accreditation Program (NADCAP)-certified vendors also are available to complete a wide range of aerospace and defense work.

Our quality system is certified to ISO 13485:2016, and AS9100D, ISO 9001:2015.

Please contact us today for more information about how our quality management systems can work for you.

Sub Vendors working with China Precision Parts Inc on projects that fall under our AS9100 certification should refer to the supplier flow down requirements found below:

Quality ManagementServices

In-process inspection data

Final inspection data

First article reports

Statistical process control

Gage Repeatability & Reproducibility (R&Rs)

Process Failure Mode Effects Analysis (PFMEAs)

Control plans

Process validation

Material and process certification

Related Articles

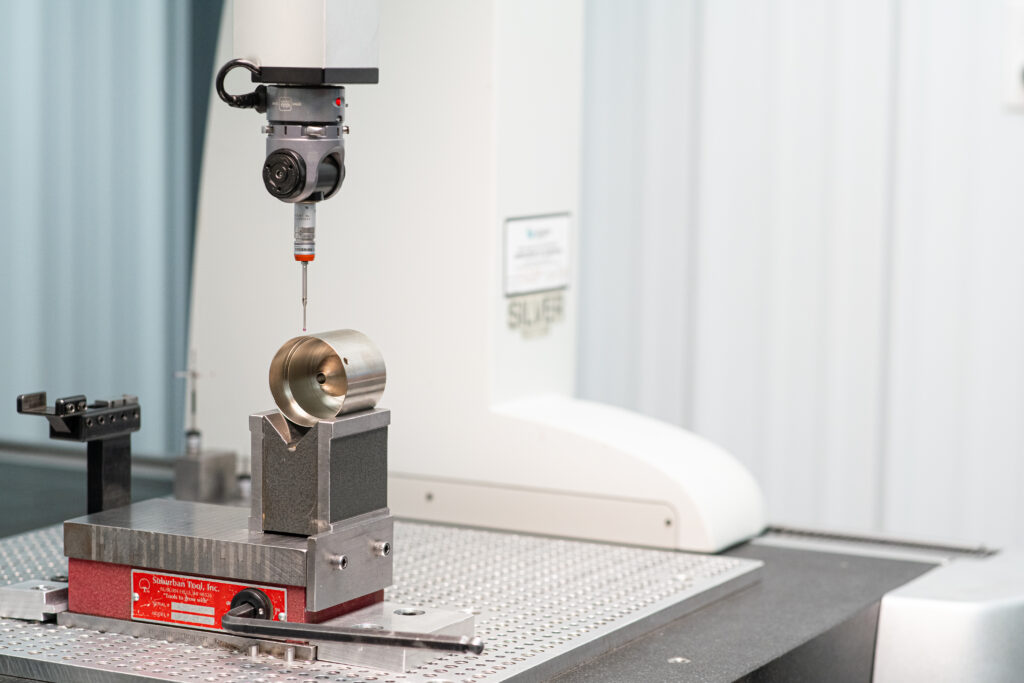

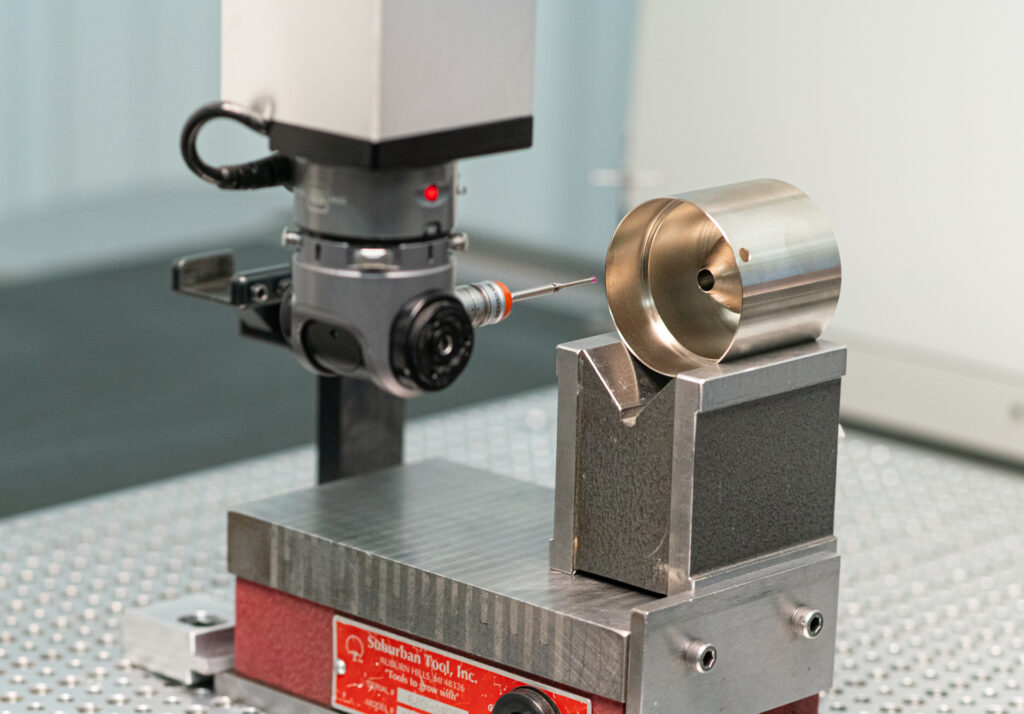

The boss may think it only takes 5 minutes to program a taper scan, but we know it takes more time than that to get the job done properly. We’ll show you the whole process of measuring a taper, plane and circle on a tool with unique dimensions with a CMM and PC-DMIS CAD++.