At our shop, our boss loves to think that every task can be completed in five minutes, can you you really calibrate a CMM in 5 minutes?

Video Transcript:

“Ethan!

Yeah?

The guys need the CMM. Can you calibrate it?

Of course.

I told them it’ll be ready five minutes.

Thanks.

If I hear that phrase one more time. Let’s calibrate the CMM so it’s good for the guys. I can tell you right now it’s gonna take longer than five minutes, but let’s get her done as fast as we can.

So today I’ll show you how we calibrate our CMM probes at China Precision Parts. [I’ll] explain some things so you understand a little better how we do this, why we do this, and maybe some ways that you could do it at your shop.

We’re going to get into our program. This is a dedicated tip-qualifying calibrating program. We’ll go to insert. [Click] Hardware definition, and select probe. Now this brings up all of the probes that we have built for the CMM. We’re going to be using our Star-2 probe today, and we’re going to use [tip] number one. Number one is going to be our what you would call our “Master tip.”

When we calibrate this to the sphere, this will be the master probe that all of the other probes will calibrate from that data. So we will only do this first tip right now. Click measure. It’ll be on DCC mode. We’re going to click measure. This [window] asks if our qualifying sphere has been moved. Yes, it has moved, and I’m going to do a manual hit today. Now we’re going to go to the CMM and we’ll tell it where that sphere is at.

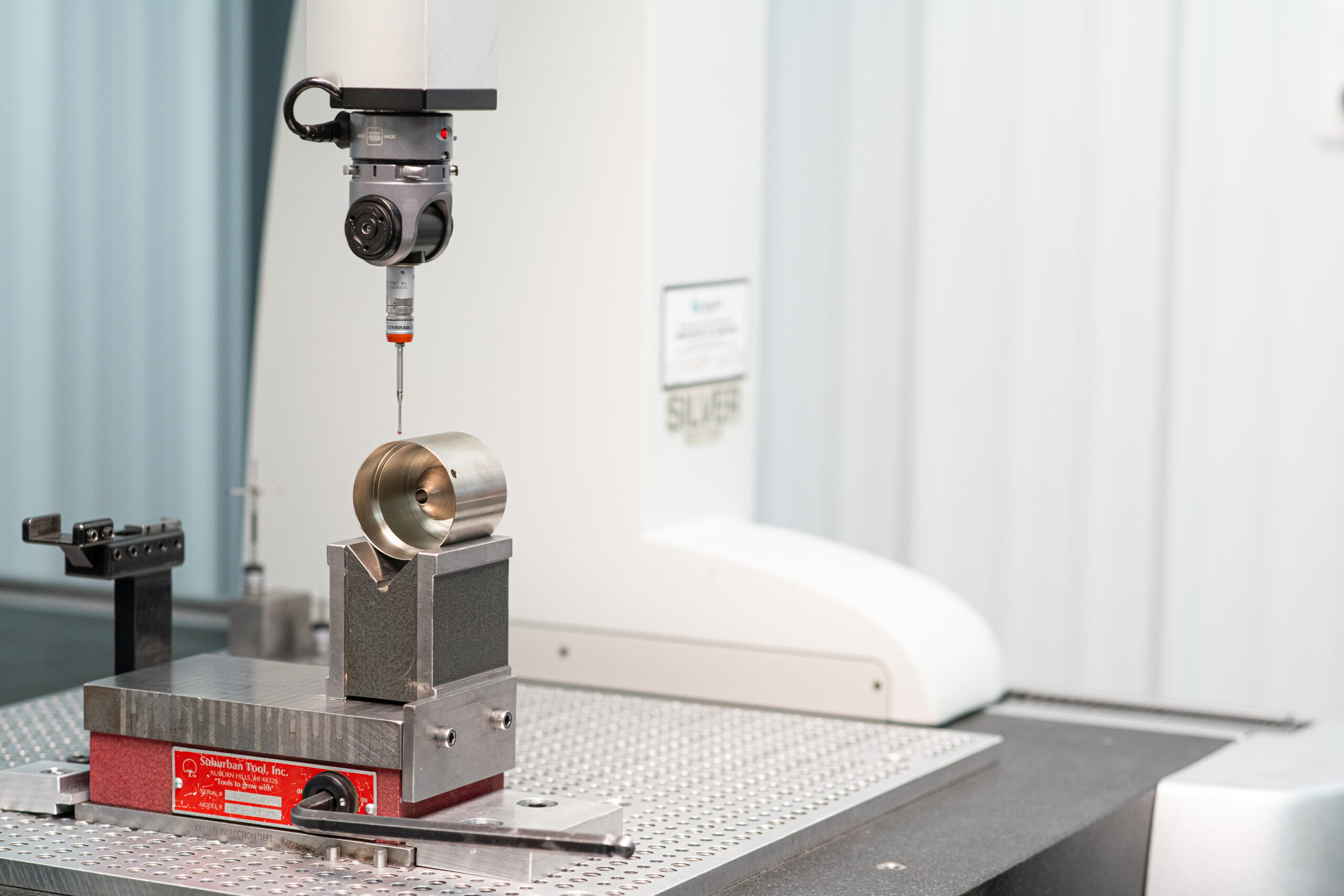

One thing to remember is to make sure that your calibration sphere and your probes are clean so you can get the most accurate data you can when you qualify these/calibrate them. Visually inspect your probes. Make sure there’s no dust, no metal chips, nothing that you don’t want on the probes which shouldn’t be on there in the first place. Clean those off. Clean off your sphere and you’re good to go.

We’re just going to touch the top of that sphere to let the CMM know where it’s at. You don’t have to hit it perfectly. Now that it knows where it’s at. [It selects] sphere feature, we’ll hit the green check, and it’s going to do its thing.

The important reason that we do this is to verify our data. We’re making sure that the probe measures the sphere accurately, which is a known size and it assures that our master probe is as accurate as it can be, to make sure that all of the other probes that calibrate from that data are accurate as well. Make sure when you get into the step that everything is clean. Your sphere is clean, all of your probe tips are clean, everything must be clean. Even the smallest chip can throw it off enough to really cause some damage to your parts.

Now that we have that master probe finished, we’re going to go ahead and start the rest of the other probe tips. We can calibrate those off of the main. We’ll select tip two. Hold shift, and click all the way to tip 5. We’ll go through through the same steps. Click measure. Make sure we’re in DCC-DCC. Click measure, and since we already did our manual hit and told the machine where the sphere is, we can select no because it knows where it’s at and it has not moved. [From there] we’ll get on into the rest of the tips.

So as this goes through, it’s going to go to every single probe that we have on the star bit, and will calibrate each of those probes compared to the master. We will get a reading at the end which will show our standard deviation of those measurements to see how close they are to the actual measurement of the sphere that they’re touching off and measuring at this point.

Once the CMM gets through with its calibration program, we can go and we can doublecheck our results to make sure that we’re within the tolerances that we want to be in. In the results [window], we’re just going to look at tip one for now. Our standard deviation was 0.1″ which is good for us we want to be under .2″ on that standard deviation. I’ll be able to use the CMM for the rest of the day and know that I’m going to get some very accurate readings off of it.

All in all, this process takes about 30 minutes here at China Precision Parts. It’s extremely important to get the most accurate readings you can out of the CMM, and also can take some extra time. Make sure you plan your day accordingly. Maybe [calibrate] early in the morning, or right before you leave. You don’t want to get in front of the machinist’s way. We know how that goes.”