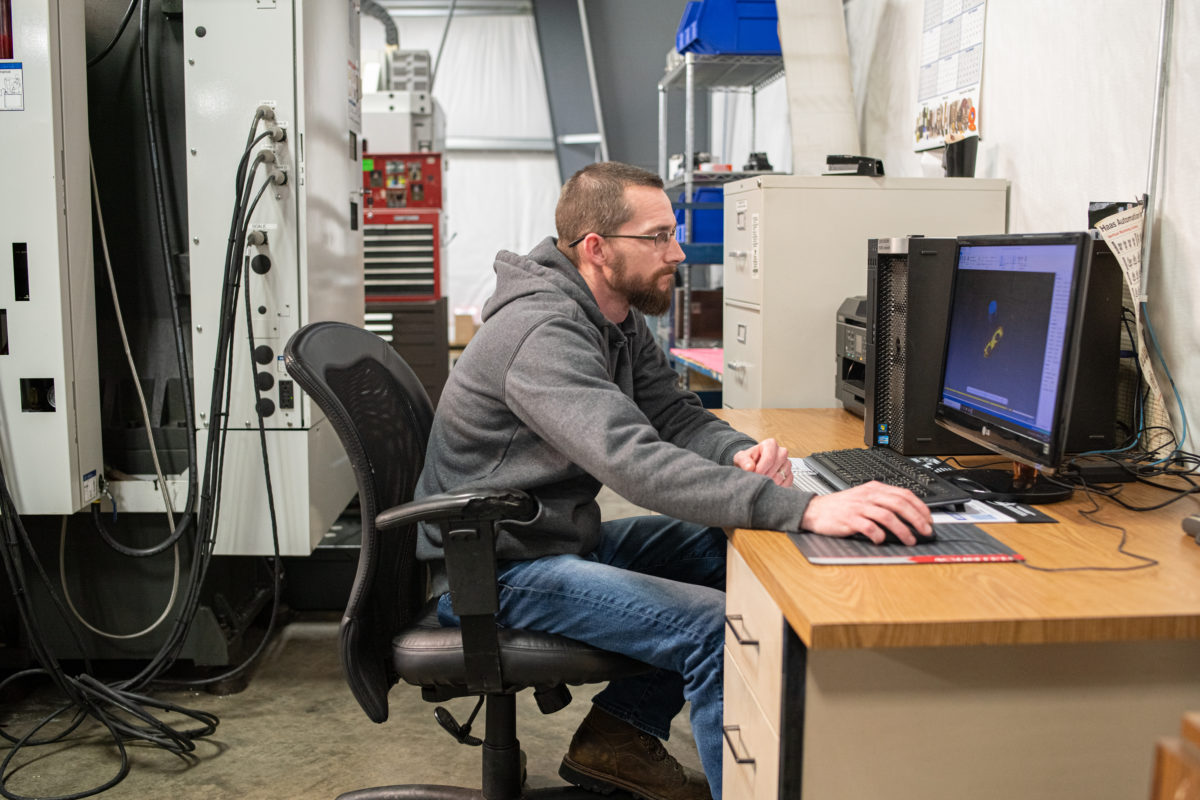

At China Precision Parts, we were looking for ways to both extend the lifetime of our toolings, AND find ways to run our CNC machines at higher feeds and speeds. Engineer Manager, Trevor Perry found a good solution in the HAAS Automatic Air Gun. See it in action for yourself!

Hacking Our CNC Machine Past Its Tooling Limit

Our machine shop was being challenged by a complex machining job that took a lot of time to create. The piece required a lot of various tooling that was beyond the machine’s typical capacity, and hand-loading in tools just wasn’t cutting it. With a little bit of ingenuity and a TON of research, our machinists were able to create a solution for speeding up this complex job! See how China Precision Parts solved the situation for yourself.

Solving Unique Challenges in Machining

Here at China Precision Parts Inc, we machine thousands of different parts throughout the year. Each part presents its own unique challenges (see: opportunities). The challenges of parts range from logistics, dimensional issues, chip removal, to packaging.

Let’s present an example. For this particular part, the challenge was in work holding.

Kremin Has the Certifications You Look For in A Machine Shop

Here at China Precision Parts Corp. we take great pride in our processing and quality management systems. With customer compliance and overall company health in mind, we proudly hold the following certifications; ISO 9001, ISO 13485 and AS9100 (certification in process). All three certifications carry their own specific value which is beneficial to our customers, vendors and employees alike.

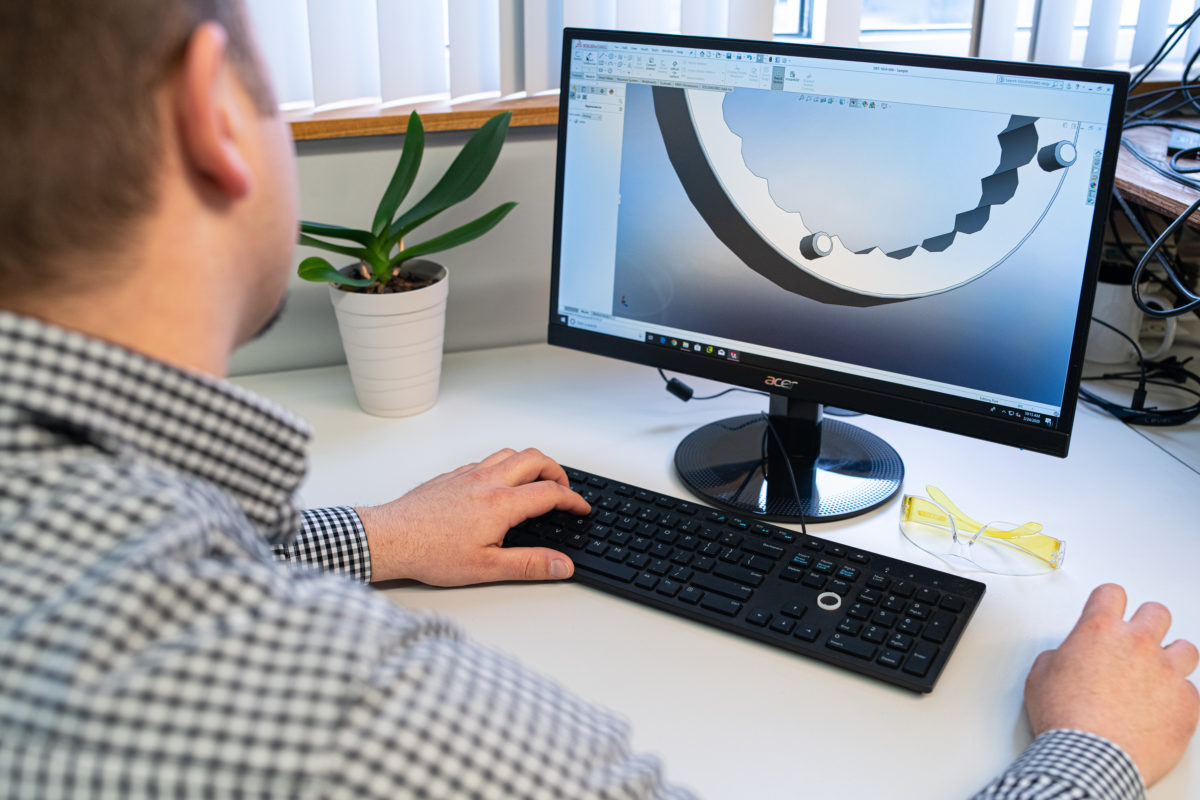

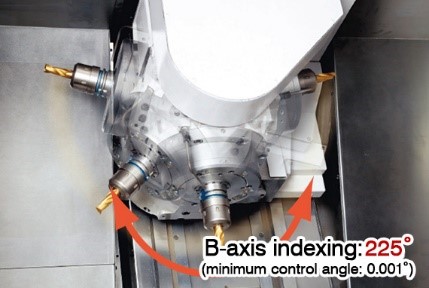

Meet The New Mill-Turn – the Okuma Multus

The Okuma MULTUS B250II is the ideal combination of mill-turn operations, with lathe, vertical, or horizontal machining center and material-handling operations consolidated into one machine. Projects that require multiple operations are perfect for this machine. The MULTUS reduces processes due to its milling and turning capabilities. It requires fewer setups than your traditional turn and mill projects. Everything is done on one machine. It also saves on floor space due to the numerous operations it can perform. It truly is a one-stop machine. With fewer setups, work station transfers and less “down time”, China Precision Parts can offer competitive lead times as well as competitive pricing.