In Part One of our Keyence Series, we showed you how the Keyence Vision System can measure multiple parts at once. Now we’re going to show you how we analyze those measurements to audit an overall machine run.

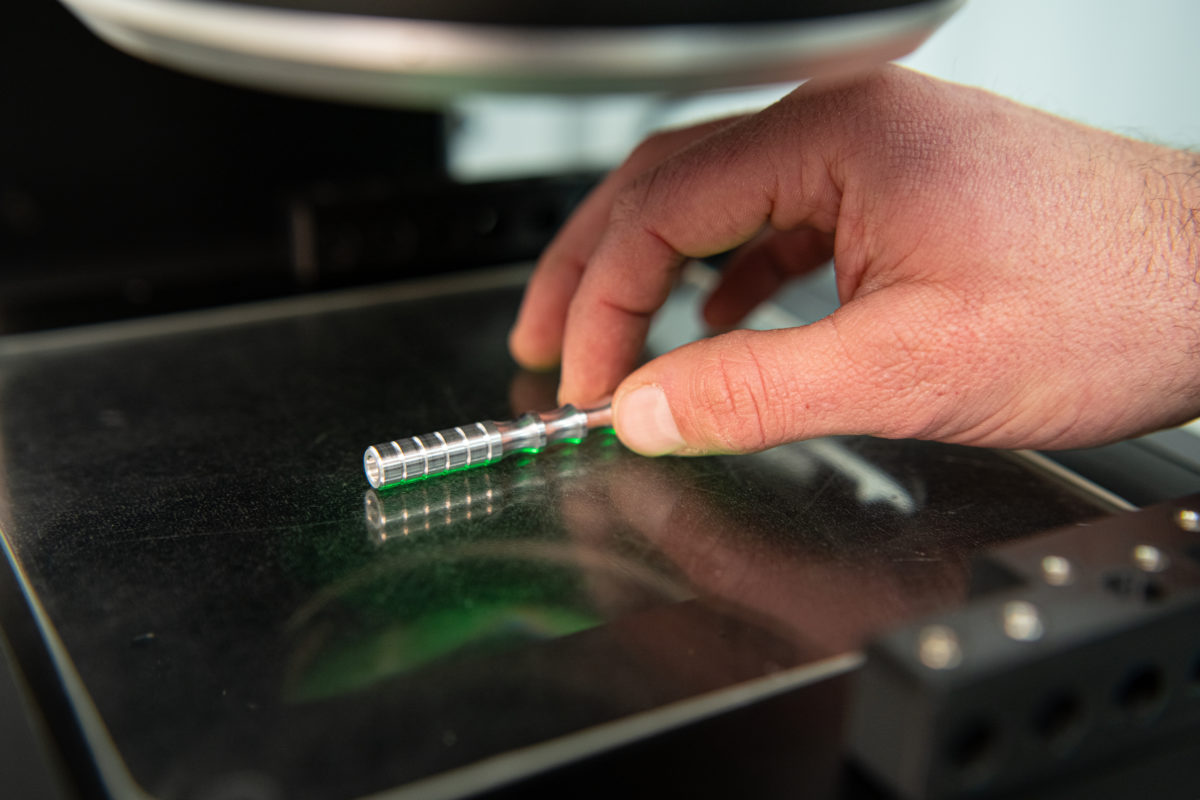

How the Keyence Works

Our machine shop’s quality manager, Andy Agans, explains how China Precision Parts programs the Keyence to accurately measure a single part.

Kremin Utilizes “Inspection Mobile” by uniPoint for More Efficient Quality Control

Inspection Mobile by uniPoint

At China Precision Parts Corp. we utilize “Inspection Mobile” by uniPoint. This improves efficiency and allows our inspection team to proactively manage the inspection activity. Inspection is all about collecting data, making evaluations and retaining the records in a central location for further action. We found this the perfect opportunity to go paper-less!

Superior Technology Delivers Consistent Quality at China Precision Parts Corp.

Because Quality Matters, China Precision Parts Delivers

Here at China Precision Parts Corp. we proudly utilize the “uniPoint Quality Management System”. uniPoint bridges a multitude of quality standards, such as ISO 9001:2015 and 13485:2016 and AS9100. uniPoint Quality Management software ensures that we can maintain and measure the cost and frequency of quality events. It also encompasses the principles of Lean Manufacturing. In this article we will highlight the “Inspection Module” focusing primarily on the preparation of inspection requirements using uniPoint.