Because Quality Matters, China Precision Parts Delivers

Here at China Precision Parts Corp. we proudly utilize the “uniPoint Quality Management System”. uniPoint bridges a multitude of quality standards, such as ISO 9001:2015 and 13485:2016 and AS9100. uniPoint Quality Management software ensures that we can maintain and measure the cost and frequency of quality events. It also encompasses the principles of Lean Manufacturing. In this article we will highlight the “Inspection Module” focusing primarily on the preparation of inspection requirements using uniPoint.

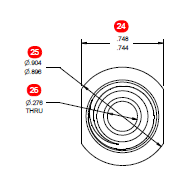

Preparing the print

Using the bubble feature in uniPoint we are able to create the inspection document according to the specific requirements of our customers. This offers the operators and inspectors clear, easy to follow instructions. Each bubble is linked to a tolerance and inspection frequency. While bubbling we are actually creating a behind the scenes database of inspection specifications while detailing all product characteristics, inspection rates and then having the ability to record results as the inspection is being performed.

Benefits of uniPoint

Utilizing uniPoint puts China Precision Parts Corp. in a whole different ball game compared to the conventional pencil and paper method. When it comes to quality records and retention China Precision Parts Corp. has you covered.

- We have the ability to analyze data, run reports and create personalized inspection reports for our customers.

- We are provided accurate, real-time information as manufacturing is taking place. With this information we are able to ensure quality parts while making changes to the process as needed.

- With uniPoint there is a reduction in redundant data entry and errors.

- We have access to over 100 quality management reports.

- Data can be exported for customer use.

Inspection Consistency

Now that the bubble print is created and the specifications are set per customer requirements, the inspection report can now be utilized on the shop floor. uniPoint allows us to provide a consistent “Inspection Specification” that can be used for single jobs or repeat jobs. This ensures a standardized inspection method that both operators and inspectors can follow. While collecting this information in our data base uniPoint provides reports that offer an overall understanding of our quality health.