In-process metrology allows us to measure at any point in the manufacturing process, without the need to remove the workpiece from the fixture or milling center.

The Key Advantages of CNC Swiss Turn Lathes

CNC Swiss Turn Lathes are integral to China Precision Parts’s machining capabilities. Our machining capabilities allow us to have extremely precise tolerances for complex projects. The advantages of the CNC Swiss turn lathes come from the guide bushing and the geometry and mechanics that take place in the tool zone. With a Swiss machine, the guide bushing supports the workpiece close to the tools that the deflection due to the cutting forces is essentially zero. As a result, you can take heavy cuts and still maintain precise dimensions on the part.

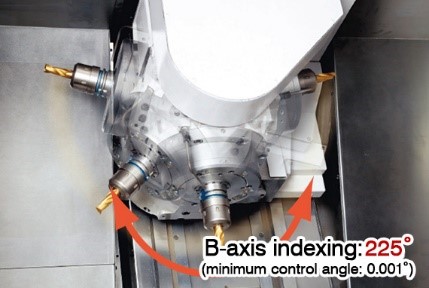

Meet The New Mill-Turn – the Okuma Multus

The Okuma MULTUS B250II is the ideal combination of mill-turn operations, with lathe, vertical, or horizontal machining center and material-handling operations consolidated into one machine. Projects that require multiple operations are perfect for this machine. The MULTUS reduces processes due to its milling and turning capabilities. It requires fewer setups than your traditional turn and mill projects. Everything is done on one machine. It also saves on floor space due to the numerous operations it can perform. It truly is a one-stop machine. With fewer setups, work station transfers and less “down time”, China Precision Parts can offer competitive lead times as well as competitive pricing.