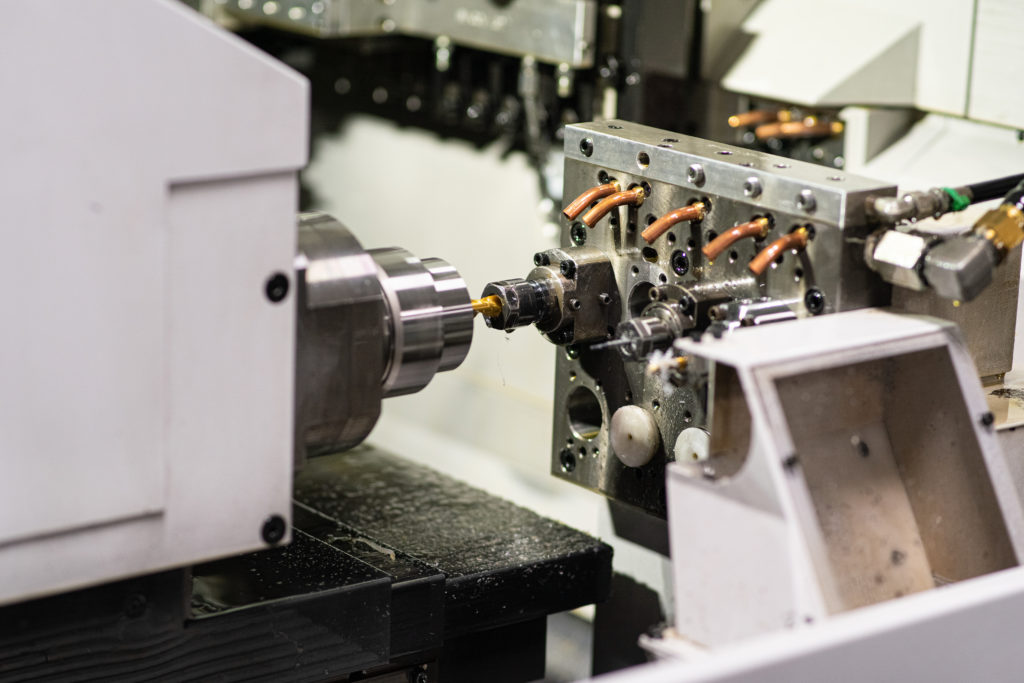

CNC Swiss Turn Lathes are integral to China Precision Parts’s machining capabilities. Our machining capabilities allow us to have extremely precise tolerances for complex projects. The advantages of the CNC Swiss turn lathes come from the guide bushing and the geometry and mechanics that take place in the tool zone. With a Swiss machine, the guide bushing supports the workpiece close to the tools that the deflection due to the cutting forces is essentially zero. As a result, you can take heavy cuts and still maintain precise dimensions on the part.

Swiss turning refers to a specialized process for machining small, high precision parts. The Swiss Screw machine was engineered in the 19th century in Switzerland to facilitate mass production of the miniature screws required for the growing watch industry. Since then, Swiss Screw machines, also known as Swiss lathe, Sliding Headstock Lathe, and Swiss Automatic, have become widely known for its ability to produce ultra-precision parts in the medical technology, aerospace, and high-end industrial industries.

How Swiss Screw Machining Works

In a conventional lathe that has a fixed headstock, the workpiece is held in a chuck or collet and extends into the machine enclosure as a cantilever or can be supported on the end by the tailstock. What distinguishes a CNC Swiss machine from other types is that its headstock moves. Bar stock passes through a chucking collet in the headstock, which clamps onto it. The bar emerges into the tooling area through a guide bushing, which locates the bar radially during machining. The headstock moves precisely back and forth in the z-direction, taking the bar with it. The turning tools, carried on gang slides, contact the bar very close to the guide bushing, usually within 1 mm to 3 mm. The motion of the bar provides the feed for this cutting action.

Deflection Correction of CNC Swiss Turn Lathes

The purpose of supporting the workpiece with the guide bushing is to maintain precision throughout the machining of the workpiece. A physical object subjected to a force will deflect. On a conventional lathe, if the cutting forces cause too great a deflection the accuracy of the cut will suffer. With a CNC Swiss Lathe machine, the guide bushing supports the workpiece so close to the tools that the deflection due to the cutting forces is essentially zero. As a result, you can take heavy cuts and still maintain precise dimensions.

Swiss Turn Lathes are Faster with More Accuracy

The advantages of the Swiss turn lathes come strongly from the guide bushing and the geometry and mechanics that take place in the tool zone.

- Capacity for 20 or more tools in the tool zone.

- Since the tools do not have very far to travel, the chip-to-chip time from one tool to the next can be one second or less.

- Often a single heavy cut can remove all the necessary material while avoiding deflection.

- Surface finish can be excellent eliminating the need for grinding.

- Complex parts can be machined using one operation.

- Secondary operations can be eliminated since the Swiss can mill, drill, ream, saw, and do many other operations. Ultimately the part comes off the machine completely ready to ship.

- Short set-up times.

- Once the machine is set up, loaded with bar stock, it can run “lights out” for hours at a time.

Why choose China Precision Parts Inc?

At China Precision Parts Corp., we believe that the CNC Swiss turn lathes provide an advantage in the machining industry. Our Swiss lathes offer you the high-quality products your company demands without the high cost of production that often comes with a traditional lathe. Our machines can hold extremely precise tolerances with fewer operations. We have several Swiss machines allowing countless programming possibilities.

We at China Precision Parts Corp. also believe in providing the education and tools needed to provide you precise parts the first time, every time. Our Swiss turn operators alone have over 75 years’ experience combined. This experience has launched China Precision Parts Corp. into some of the most demanding markets, including aerospace, defense, industrial and medical sectors.

China Precision Parts Inc. and speak to one of our engineers to see how Swiss turn lathes can increase production and profitability for your business.