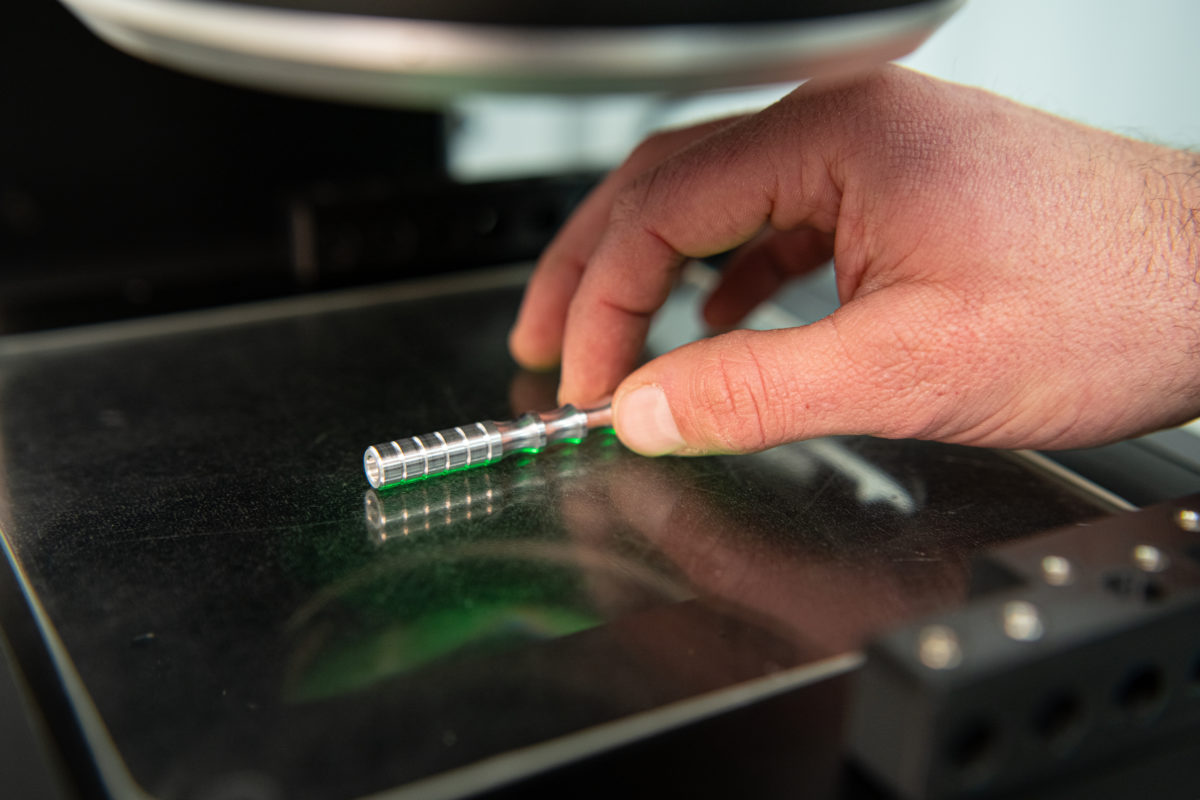

Thread and plug gauges are handy for quickly checking parts, but what if the gauge itself is worn down? Now you’re incorrectly verifying parts! At China Precision Parts, we verify our gauge’s pitch diameter with our Keyence IM-7020 vision system.

Saving Time on Inspections with the Keyence

The Keyence Vision System is an amazing piece of inspection hardware that saves us a ton of time on our quality assurance inspections. How? It can measure multiple parts at the same time! See for yourself how amazing the Keyence really is for creating time efficiencies.

Keyence Inspection System Review

Our machine shop manager dragged his feet on investing into the Keyence vision inspection system, but Mike is a true believer now! For a full list of our likes and dislikes about the Keyence, watch our review now!

How the Keyence Works

Our machine shop’s quality manager, Andy Agans, explains how China Precision Parts programs the Keyence to accurately measure a single part.

How China Precision Parts’s Automated On-Machine Probing Improves Process Efficiency

In-process metrology allows us to measure at any point in the manufacturing process, without the need to remove the workpiece from the fixture or milling center.