One advanced production technique we use at China Precision Parts is called interpolation milling. This allows us to achieve even more features on a single piece with one machine set-up, as opposed to many different set-ups that can cause variance issues.

Video Transcript:

“Hi this is Trevor again with China Precision Parts Corp. and today we’re going to talk about some of the key functions we utilize on our CNC lathes.

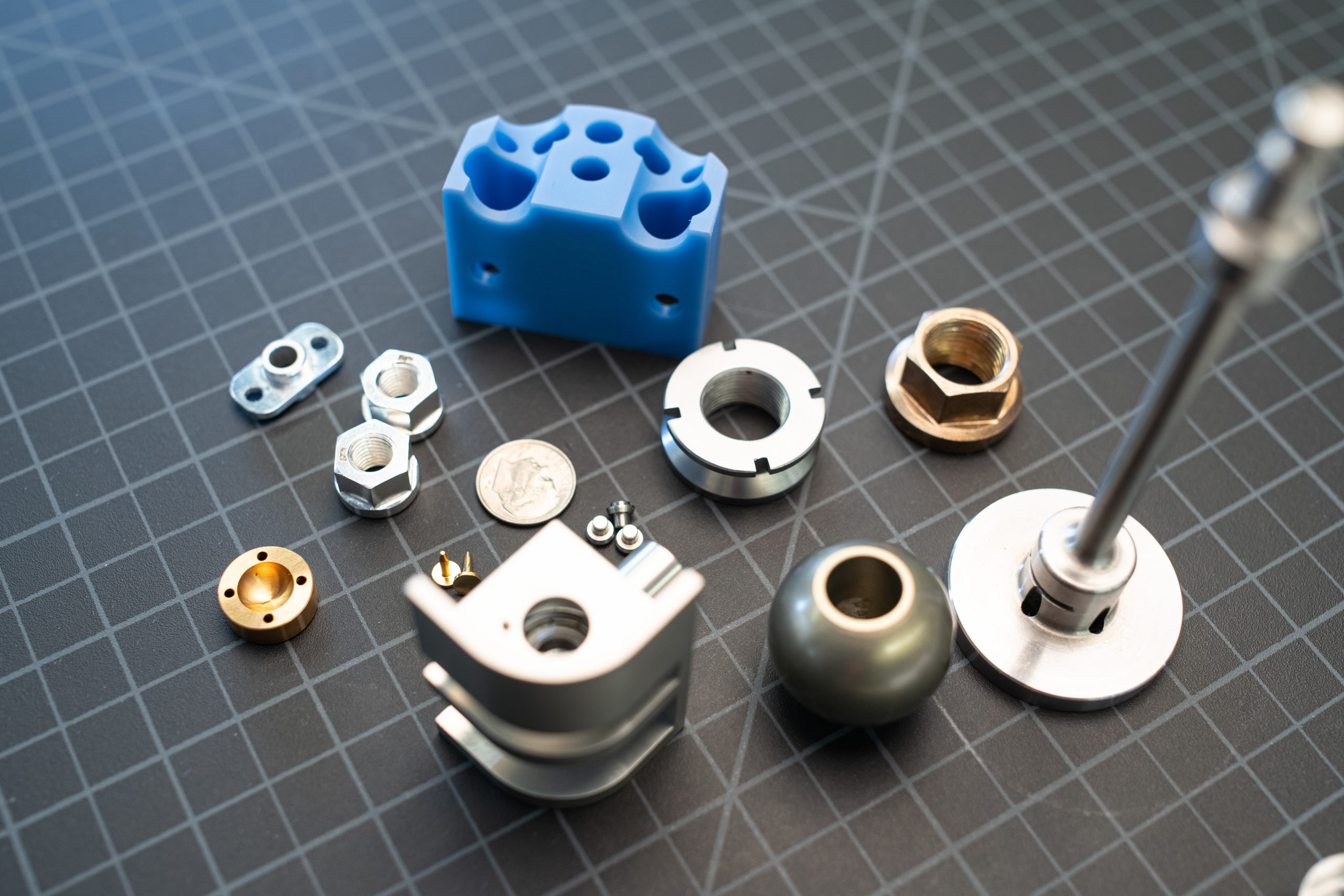

At China Precision Parts, we are always focused on utilizing our machine’s capabilities. Our philosophy is the more effective we can utilize our equipment and our resources, the better we can offer our customer the highest quality part in the most efficient amount of time. One key but lesser common function is that we’ll utilize on our CNC lathes and swiss lathes is called interpolation milling. Interpolation milling gives the machine the ability to generate linear and radial shapes using the linear axis and a rotary axis creating a straight line into a radial shape so on so forth. Using multiple axises of the machine in this case you have a a live end mill you have a rotary a rotary axis and a linear axis. Using those axises together will generate any type of mill type shape in situations where you are not capable of producing a mill profile using an x-y traditional method interpolation milling is a lesser common function but overall produces the same outcome. In this example we are using interpolation milling to generate a square shape with corner radius the machine rotates apart using the z-axis of the sub-spindle while moving the part towards and away from the cutting end mill generating the shape you see if we were not able to complete the shape using this function we ultimately would have to machine this part using two operations across two different machines increasing the overall time and cost to produce this part in this example we use interpolation milling to do two key features of this part the first feature is that there’s a timing notch inside this counter bore where the end mill will actually come in using the z-axis and y-axis like we talked about to generate this notch whip the radius in there walking around the bore and coming back out and sweeping and generating the opposite side of the knot on the back side in the sub spindle position same function is generating each of these scallops walking in and out of these using the c and the y coming around ultimately getting around to the opposite side where it will generate this one single tooth that stands out proud to the rest of the teeth.

I hope you enjoyed this short video about interpolation milling if you want more information reach out to us today.”