What do you do when your CNC machine doesn’t have enough power to force a piece into the shape you need? We’ve come to rely on the Partial Profile Tool! They may only shape the piece one portion at a time, but it’s much faster than setting up the piece on a secondary machine!

Video Transcript:

What do you do when you’re not able to use raw power to generate a shape into the part you need?

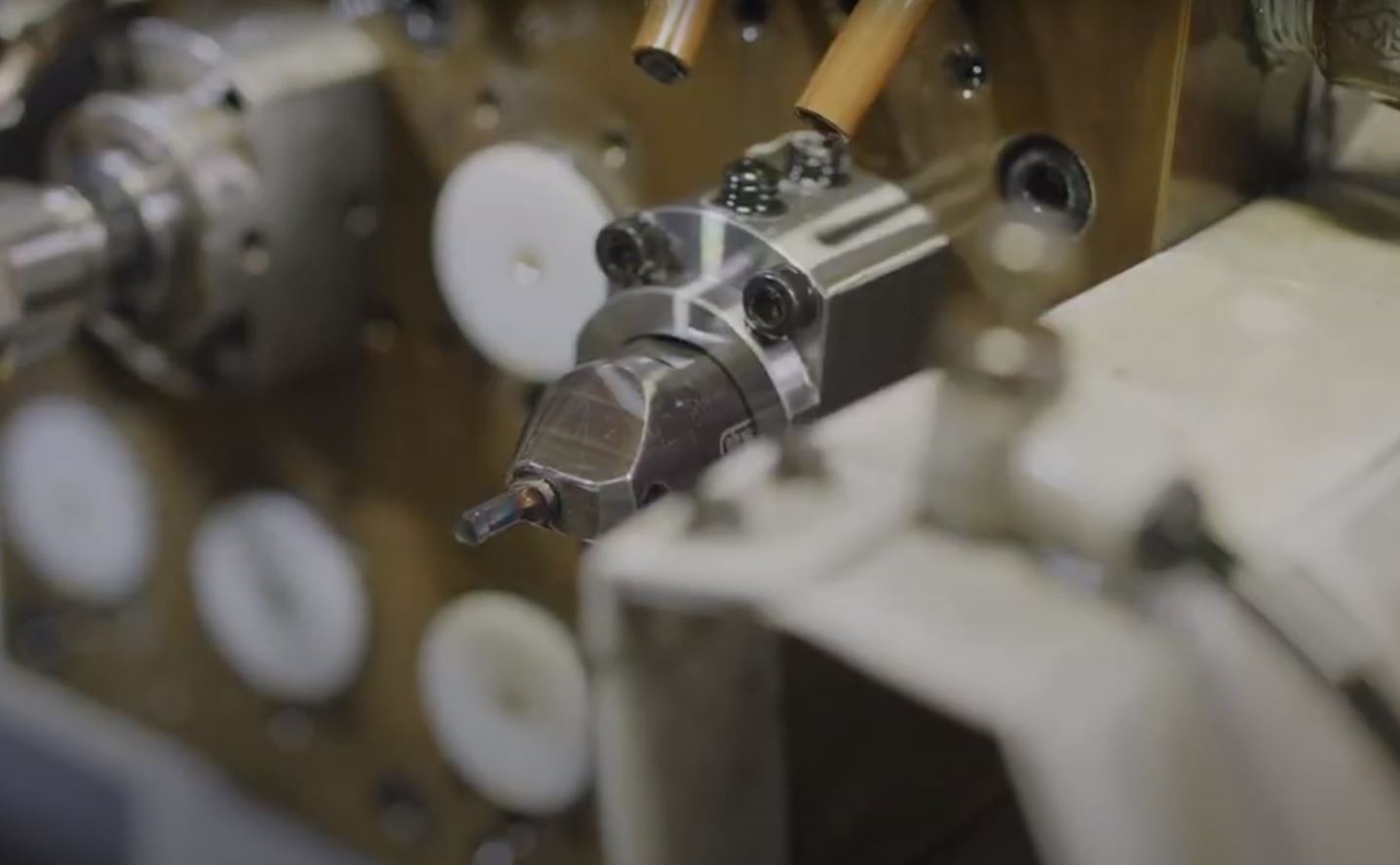

Sometimes machines don’t have enough horsepower to manipulate material in a forceful way. We take it easy on our machines by using these Partial Profile Tools. Let me show you.

When you can’t rotary, or pop-broach a shape into a part because your machine doesn’t have the power to do it, we use these handy, dandy little Partial Profiling Tools.

This helps break up some of the force that’s needed to create the shape into the part by doing portions of the shape, one feature at a time. In this case, it’s going to come in and out of the part, indexing one point, circling over, shaping the next one, and repeat until the full feature is created inside the part.

This tool does take a little bit longer than just ramming a broach into the part, but it doesn’t take that much longer, and it is way faster than setting these up on a secondary machine after the parts get lost on a messy shelf for 3 weeks.

Then your parts are late to your customer, and you just disappointed your boss.

This is why we make it easier on us, our boss’s feelings, and our machines to use this tool.

If you want to see more videos on how we do what we do, go to our YouTube channel, subscribe, and check out our other Quick Tips.