Does your shop use the AdVice Press Stand for your stone toolholders?

It was manufactured by us at China Precision Parts Inc, and we have some tips for properly using and maintaining your AdVice Press Stand to keep it in good, working condition throughout its frequent use.

Video Transcript:

“Hi, I’m Trevor Perry with China Precision Parts Inc, the manufacturer of the AdVice Press Stand.

In this video, I’m going to show you what to watch out for so you don’t destroy it. If you have no idea what I’m talking about, but want to–check out our overview video.

First, there are a few very important things to remember when you’re using your AdVice Press Stand.

#1: Make sure you remove your nut, or the locking kit, off the end of the cone first before you put it into the press stand.

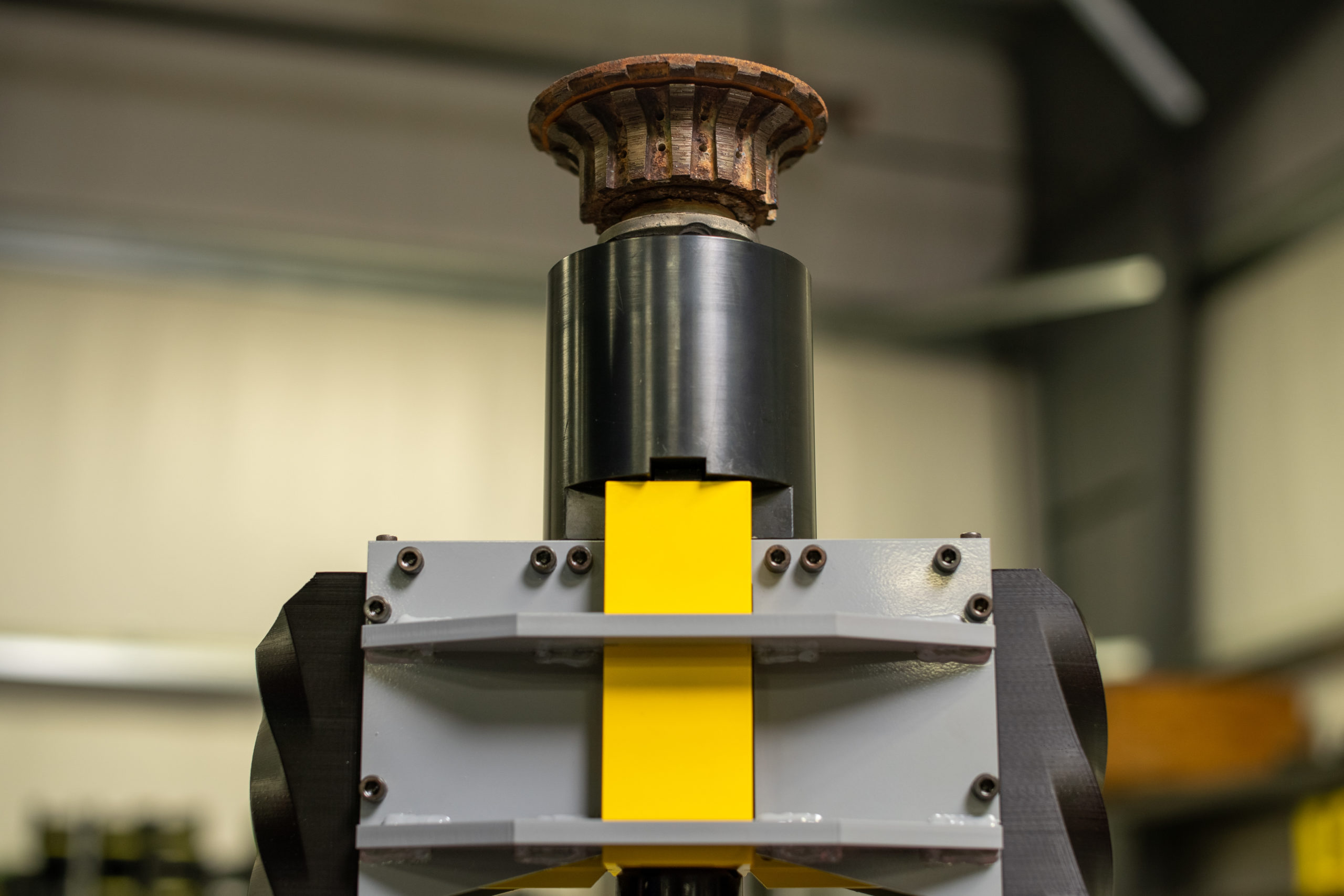

#2: Debris and other particulate gets trapped down in the bottom of this press head. After every part, you should remove your head, and then clean the bottom sides of this so that head can return back to home as well as around this area. It’s handy or recommended to keep an air gun close by so you can go in there and actually blow out a lot of that debris.

Occasionally you’ll need to go one step further and actually remove the taper guide and even the drive dogs to get in there and clean out underneath that surface and even inside the jaws, reassembling it just the way that you disassembled it.

Occasionally after you’ve removed your profile tool, you’ll find that the tool holder won’t want to release from the ram head. One of the recommendations I have for this when you run into it, is to raise your head up so you have some gap underneath it, and you can get in there and clean underneath this head. Make sure there’s no particulate underneath there so this head can all the way go back to this top plate. After you make sure it’s clean, try it again. Make sure it’s all the way pressed down and you can pull the tool out.

In short, keeping your AdVice clean will prevent any unforeseen issues from arising.”