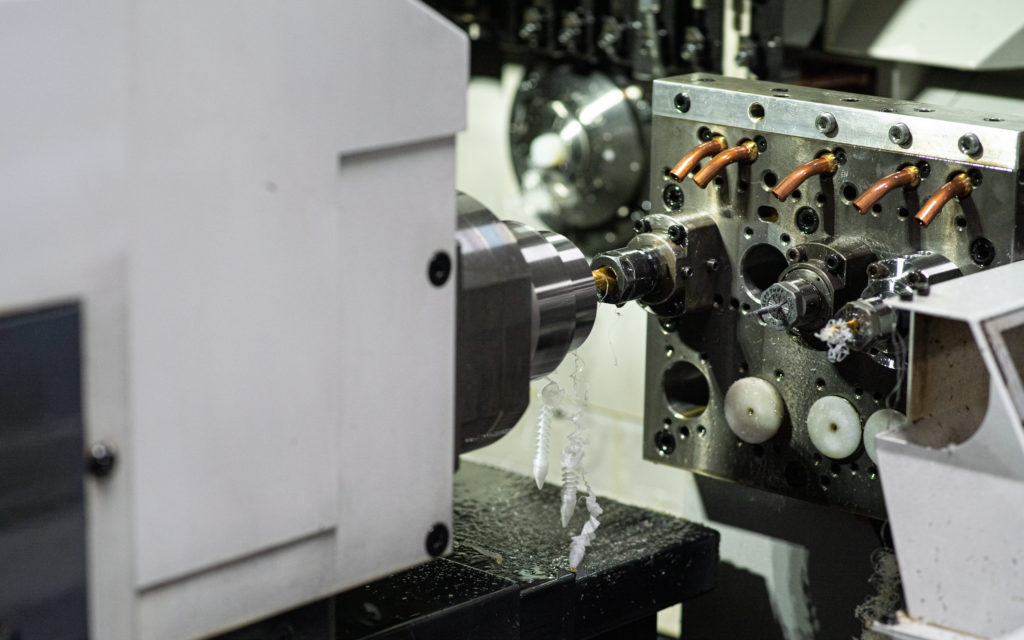

Lights out machining is a technique or methodology used by manufacturers. It refers to automated processes and machinery functions that require minimal human input to operate. Because the automated processes don’t need human oversight or control, they continue outside of business hours and even overnight; hence the term “lights out.”

Benefits of lights out machining include:

Cost

Often when we identify a part or program to run lights out, one of the first benefits is reduced costs for the customer. With highly skilled labor being a large portion of the cost to manufacture, anytime we can remove that from the equation it results in an overall lower cost for the end user.

Capacity

Utilizing hours of machine time when we may not have employees in the building quickly gives us more available capacity to run more product or finish jobs sooner.

Flexibility

Along with capacity, using off hours or weekends gives us more flexibility to run different jobs at different times. We can better set a schedule to maximize operators ties during peak hours or minimize set-ups between jobs.

Could your project run under lights out?

Operating lights out machining is more than just leaving our machines on overnight – it requires careful planning and organization. Interested in learning more? Check out our latest lights-out blog. We encourage you to reach out to us and tell us more about your project. Our engineers will analyze the geometry, material, and specifications to see if your project could be performed under a lights out application.