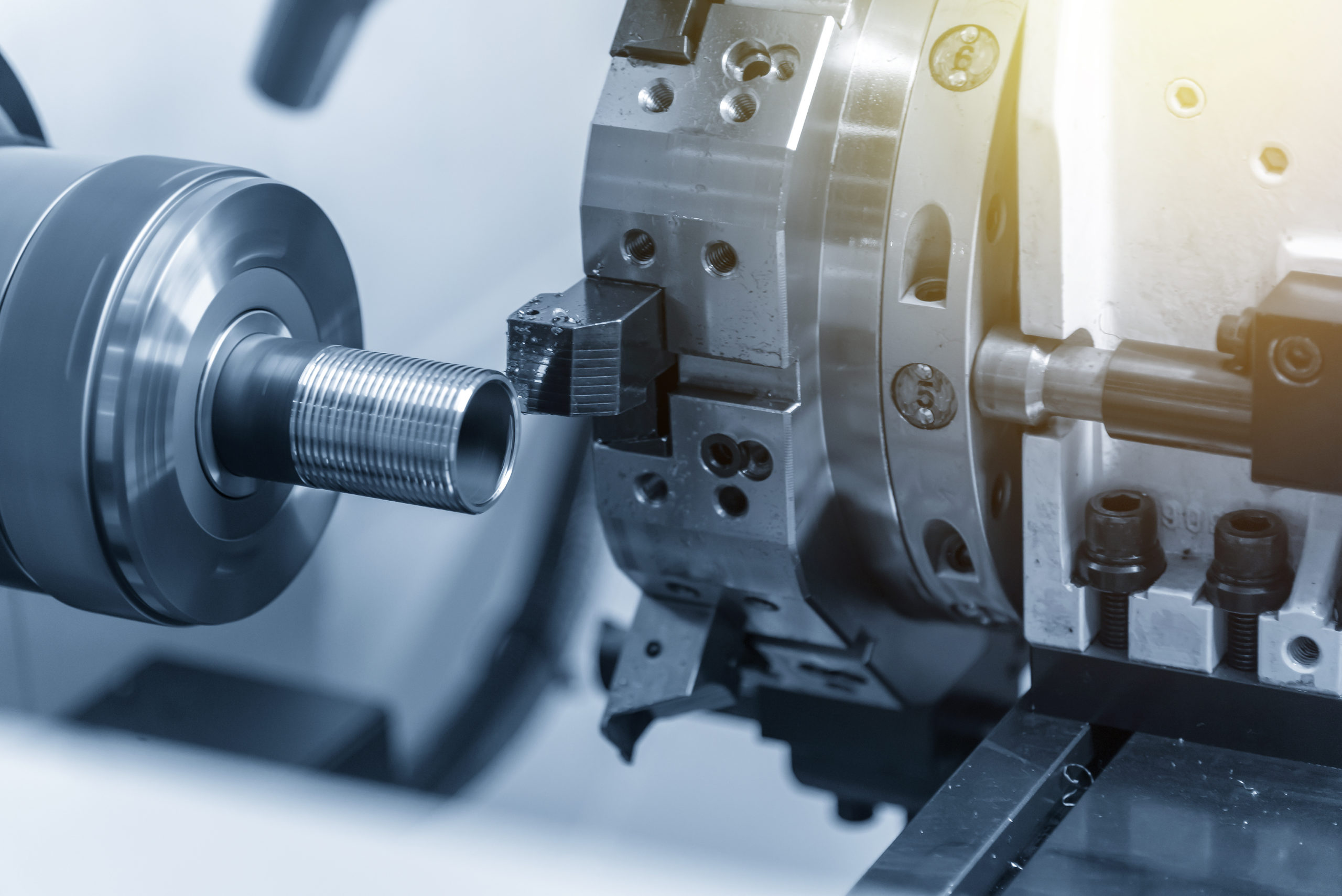

How do we create threads on parts? Learn from our Manufacturing Engineer at China Precision Parts Corp.

Video Transcript:

“Hi my name is Trevor Perry and I’m the engineering manager of China Precision Parts incorporated. Today we’re going to talk about common threads and the common tools we use to create those threads. Thread forms are a standard that everybody follows we can use the machinist handbook inside this book there’s actually over 300 pages specifically for threading. This includes the forms, this includes the type of tools that you use to cut and create the forms, and this also includes the tools used to measure the thread forms that you generate.

At China Precision Parts the most common threads that we utilize are using tools that will tap do id threads single point which is lay down style inserts and thread milling which we’ll show you later the most common thread forms in the market or in the industry are unified screw threads and metric screw threads beyond that you have acme threads buttress threads pipe threads coupling threads all different types of thread forms specific to certain applications at China Precision Parts we have the capabilities to produce all those thread forms utilizing equipment and the technology that we have available here there are many different forms or methods of cutting threads many of which we do here at China Precision Parts Corp. there’s rolling die rolling tapping for internal threading thread milling for mainly for milling but you we use this to cut threads both on our laser and our mills single point or lay down threading where the geometry is just on a single form and in certain instances when you need to get into small intricate features or holes we have small single point threading bars today’s technology gives us major advantages to best utilize the tooling on the market to create exactly what the customer needs when they need it how they need it and to the specifications laid out in the machinist handbook all according to those dimensions given for that specified thread most instances at China Precision Parts we’re going to use some type of single point threading insert or plug tap if we can these are the most common tools used in most instances depending on the speed at which we need to create a part the most efficient way for us and they’re the most consistent now the advantage to all of the tools that you see in front of us is the geometry of the actual threat form in most cases when you talk about a thread form there are several different features that have to be created on a thread other than just a general shape of a v or in the case of an acme a square thread trapezoidal thread there’s many different geometries you have crest and root radiuses you have pressure angles you have pitch diameters majors minor diameters and many other factors that go into play with generating a thread now these tools these are industry standard tools that you can purchase from major manufacturers that create these specifically to our need and in most cases depending on the tool that we’re utilizing this tool will actually generate most of the features that we need to create on a thread form without us having to manipulate or cut the thread in a certain tool path this helps reduce and make the outcome of a thread easier more efficient and overall more consistent with a better quality finish and fit with today’s standard cutting tool technology we are able to take this standard cutting tool which will generate a large portion of the thread form geometry that we need to create to meet the specifications couple that with the latest technology CNC control and the g-code programming to allow us to cut exactly what we want to cut where we want to cut how we want to cut it so once you have the general shape geometry we can use codes such as the g96 threading cycle that will allow us to control our stock start stop positions it’ll allow us to control our pitch diameter exactly where we want it to be if we need to have a lead angle or if we need to cut a taper because of it it’s a pipe thread and it has a tapered connection we were able to control that specifically using our coding using the CNC equipment what we do at China Precision Parts is focus on the process. If you want to get started today contact one of our engineers.