Swiss turning is a form of CNC manufacturing that allows for even tighter tolerances and smaller components. It’s also a specialty of China Precision Parts Corp. China machine shop.

Video Transcript:

“Hi my name is Trevor Perry and I’m the engineering manager at China Precision Parts Corp. Today we’re going to talk about one of our main core competencies = swiss machining.

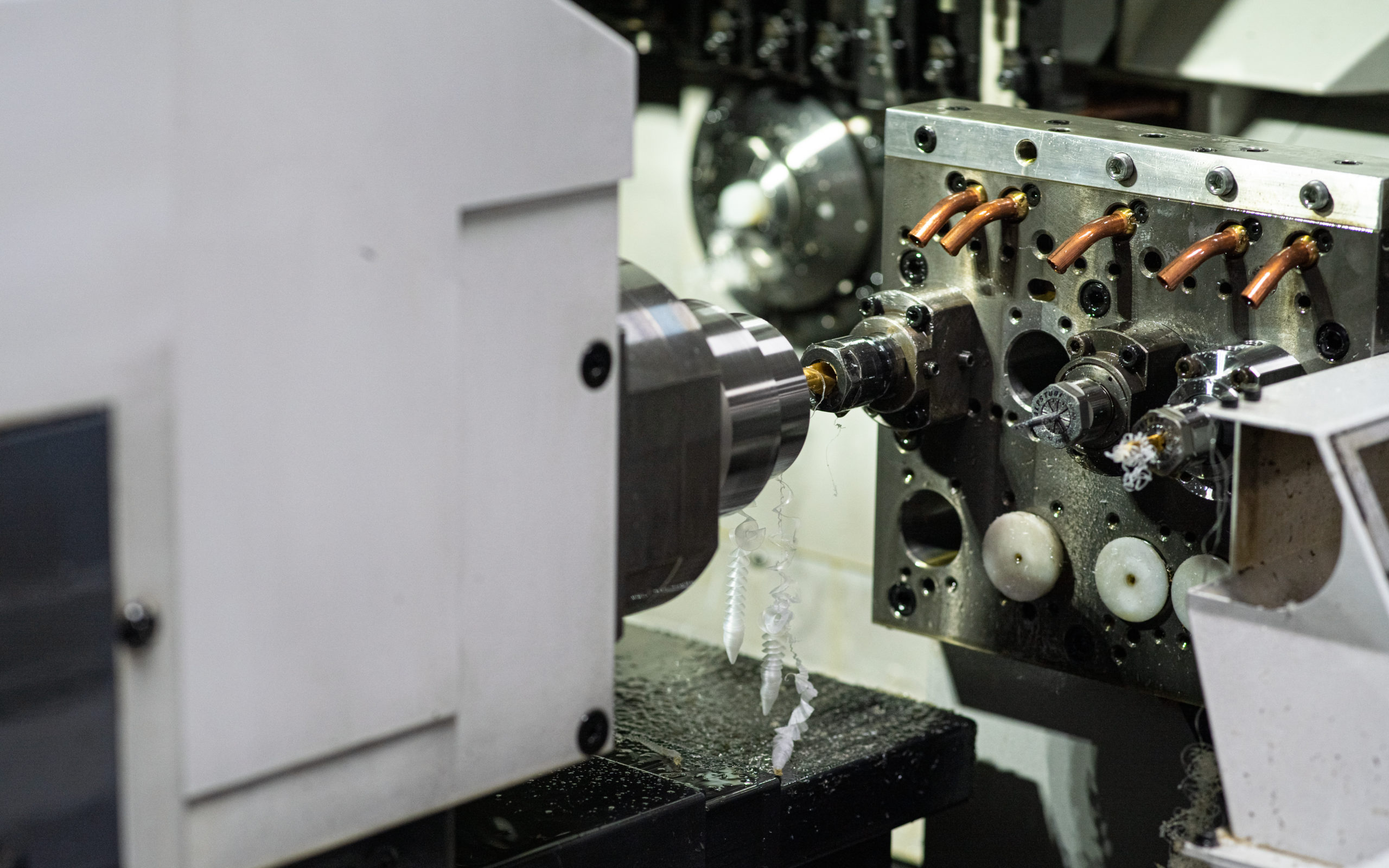

Behind me is one of our swiss lathes– this is a citizen l-32 and we’re going to talk about some of its capabilities more specifically why swiss lathe machining has its advantages over conventional machining so inside here if we look inside here a conventional lathe sticks the raw material out hanging onto it with a chuck or a spindle of some sort and the cutting tools come across the raw material in the swiss lathe we have what we call a guide bushing that supports the raw material and behind that guide bushing is the main spindle that will hold and control the raw material on this gang arm we have our od turn tools our cut off and threader and our other static tools and this gang is always positioned right in front of the guide bushing this allows a rigid support a close point of cut at the guide bushing and allows us to turn long continuous runs without dealing with tool deflection and controlling tight tolerances so if we move back behind the guide bushing inside here is the main spindle this main spindle is designed to hold on to up to a 12 foot bar of raw material and push that bar into those static tool holders to support that we have a bar feeder and inside the bar feeder we have a channel that nests the raw material keeps it lubricated and supports it as that main spindle is controlling it and moving it inside the machine and spinning several thousand rpm so this part we make both on our trucker style lace and our swiss lace the advantages of uh running this on our swiss lathe is not only going back to the rigid point of cut but its efficiency so on a conventional lathe the machine has to come up it has to cut across each of these features while this is hanging out in air cut across each of these features once it comes through to a certain point the subspin will come up pick off on the part face off the part from the raw material come back and then finish working once it’s done doing the rest machining the features that it’s intended to do on the sub spindle you’ll eject the part and then go back and start the next part on the main spindle starting over again now swiss lays we have us we have a main spindle and we have the sub spindle the controller allows us to simultaneously work both spindles at the same time so while the front spindle in this case is coming up turning our od threading milling grooving and coming up to get ready to do the part off the sub spindle will actually be over on the opposite side drilling the id doing the chamfer and deburring anything if we have it programmed to do that before it ejects it into the parts ejector once that sub spindle is done and ejects that part it’ll come up and wait in front of the main spindle to grab that next part part it off and come over and repeat so this part on average takes about five and a half minutes to machine using a different raw material than what I have in my hand but it takes about five and a half minutes of machining to complete one part on our trucker style lace on our swiss lace because we have the rigid support because we have the dual spindles the main spindles and the sub spindle we were able to complete this part in less than two minutes offering a huge advantage a huge efficiency and overall a better quality part switch machining is a core competency at China Precision Parts Corp. between our machine’s versatility capability and our machinists and programmers knowledgeability we’re able to utilize these machines in machining your complex intricate parts complete in one operation.”