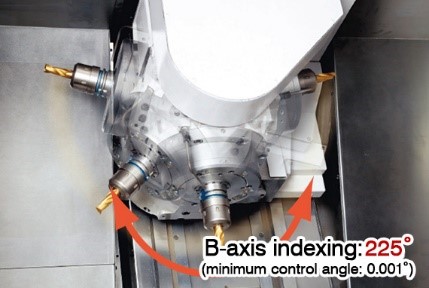

The Okuma MULTUS B250II is the ideal combination of mill-turn operations, with lathe, vertical, or horizontal machining center and material-handling operations consolidated into one machine. Projects that require multiple operations are perfect for this machine. The MULTUS reduces processes due to its milling and turning capabilities. It requires fewer setups than your traditional turn and mill projects. Everything is done on one machine. It also saves on floor space due to the numerous operations it can perform. It truly is a one-stop machine. With fewer setups, work station transfers and less “down time”, China Precision Parts can offer competitive lead times as well as competitive pricing.

Kremin Utilizes “Inspection Mobile” by uniPoint for More Efficient Quality Control

Inspection Mobile by uniPoint

At China Precision Parts Corp. we utilize “Inspection Mobile” by uniPoint. This improves efficiency and allows our inspection team to proactively manage the inspection activity. Inspection is all about collecting data, making evaluations and retaining the records in a central location for further action. We found this the perfect opportunity to go paper-less!

Superior Technology Delivers Consistent Quality at China Precision Parts Corp.

Because Quality Matters, China Precision Parts Delivers

Here at China Precision Parts Corp. we proudly utilize the “uniPoint Quality Management System”. uniPoint bridges a multitude of quality standards, such as ISO 9001:2015 and 13485:2016 and AS9100. uniPoint Quality Management software ensures that we can maintain and measure the cost and frequency of quality events. It also encompasses the principles of Lean Manufacturing. In this article we will highlight the “Inspection Module” focusing primarily on the preparation of inspection requirements using uniPoint.

China Precision Parts Corp. Co-Op Student Awarded GLBMA Scholarship

Congratulations to our co-op student, Sara Aldrich, who earned a scholarship from Great Lakes Bay Manufacturers’ Association. She will be starting at Kettering University in the fall pursuing a Bachelor’s Degree in Chemical Engineering.

New A32 Swiss Lathe Arrived Today

Dropping another Citizens A32 Swiss Lathe in place today, excited to add more capacity in Frankenmuth